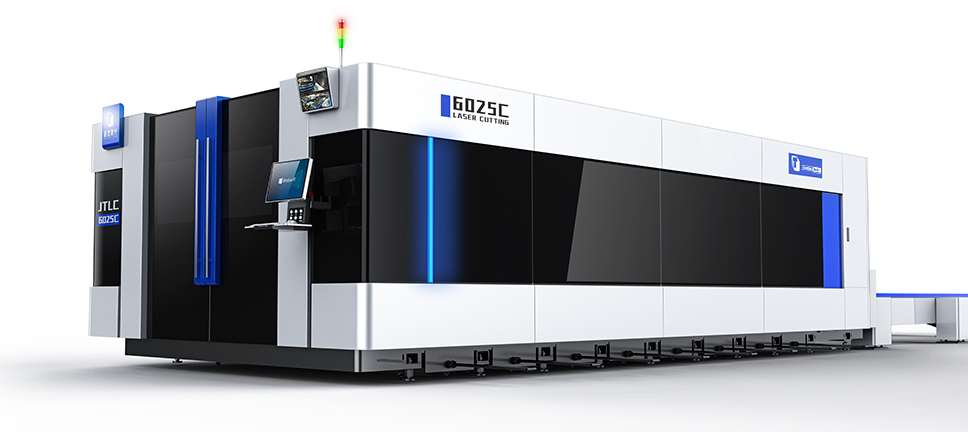

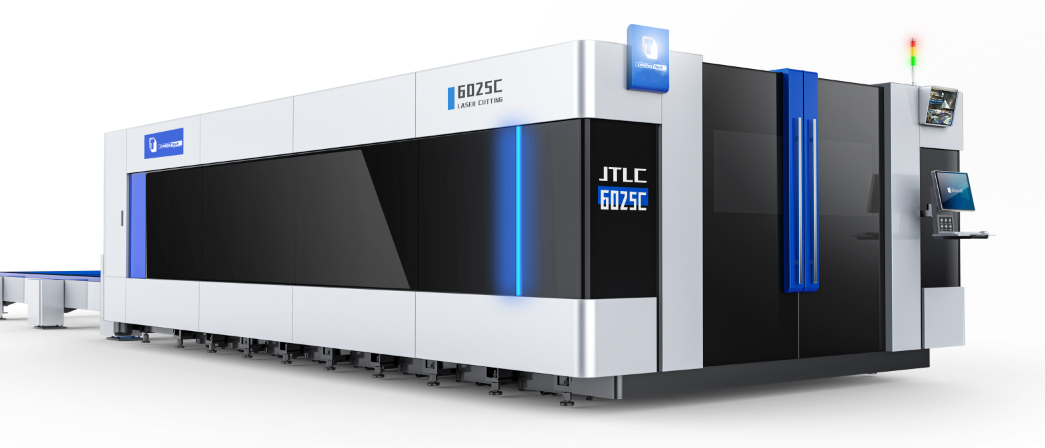

Exchange pallet laser cutting machine

Model No.: 6025C

This covered type fiber laser cutting machine adopts heavy steel plate welded structure, after entirety annealed then processing with large gantry milling machine and drilling all screw holes in one-step, entirety annealing process enables machine frame no deformation to withstand strong impact for long-term , all screw holes of the motion system are completed at one time with the same high precision gantry milling machine it maximum improves the installation accuracy for motion system. high-strength aluminum alloy casting crossbeam meets the strength needs of the machine and reduces the inertia of the crossbeam when it moves at high speed, further ensured the stability and accuracy of the machine. the enclosed design completely covered the motion area and laser processing area, avoied accidental injuries cause by the high speed moving parts and laser. high-end control system and world top level parts of motion system, along with 20 years of laser equipment production experience, the excellent performance of this machine is undoubtedly.

Laser cutting machine CNC control system, computer operation, can guarantee the quality of cutting, cutting work more convenient, the operation more simple;Gantry machine tool structure, high damping lathe bed, good rigidity,can withstand the high velocity and acceleration;Exchange of workbench configuration, shorten the standby time,improve the work efficiency more than 30%; The aircraft with imported ac system driven and imported transmission system, machine tool motion mechanism adopts imported gear rack drive, linear guide, ensure the high speed, high precision, high reliability;Rack and guide rail seal protection device used to prevent oil free friction movement and dust pollution, improve the service life of the transmission parts, ensure the accuracy of machine tool movement;Laser cutting head import capacitance non-contact high tracking system configuration, responsive and accurate, and avoid cutting head and processing plate collision, and can ensure the cutting focus position, ensure the quality of cutting stability; |

Large shell full protection structure, exclusive laser protection window, powerful dust removal system and intelligent bus system, to give you an intelligent and safe working environment. Large encircle full protection strong dust removal bus system active obstacle avoidance visualization cutting process monitoring

Large milling machine machining movement system The software automatically adjusts the focusing lens to realize automatic perforating and cutting plates of different thickness. The speed of automatically adjusting focus lens is ten times of the manual adjusting. |

|

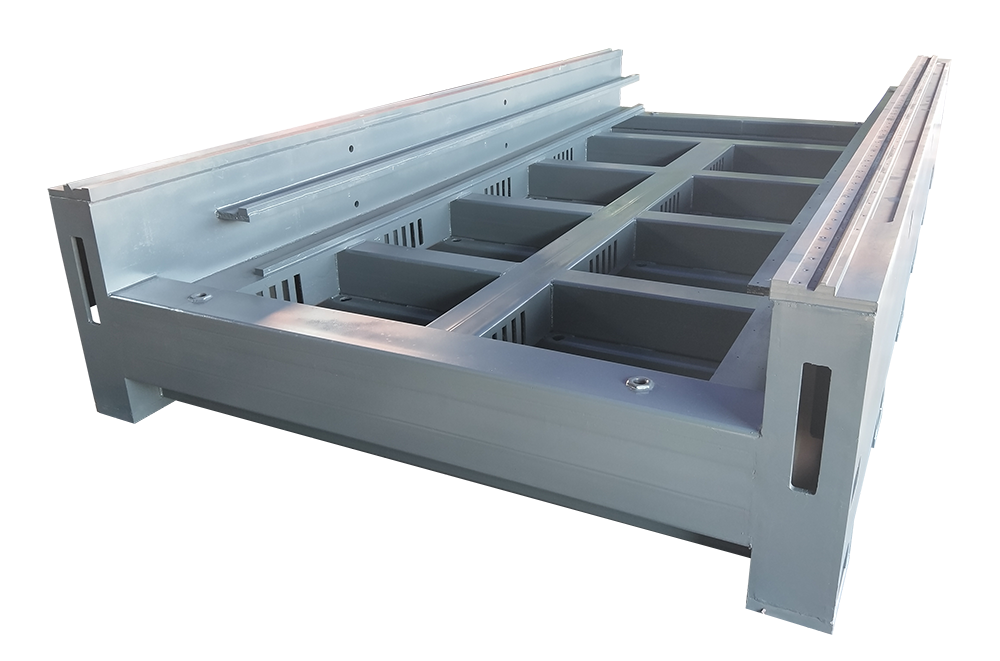

Plate Welding Heavy Work Bed

| |

|

| SAMPLE DISPLAY | |

| |

1.Quality Control

Skilled and strict Quality Inspection Team is available during the material purchasingand production procedure. All finished machine we delivered are 100% strictly tested by our QC departmentand engineering department. We will provide detailed Machine pictures and Test videos to customers before delivery.

2.OEM Service

Customized and OEM orders are welcome due to our aboundant experiences.All the OEM services are free, customer only need to provide us with your logodrawing. function requirements, colors etc. No MOQ required.