Mould laser welding machine

Model No.: YWD200MD

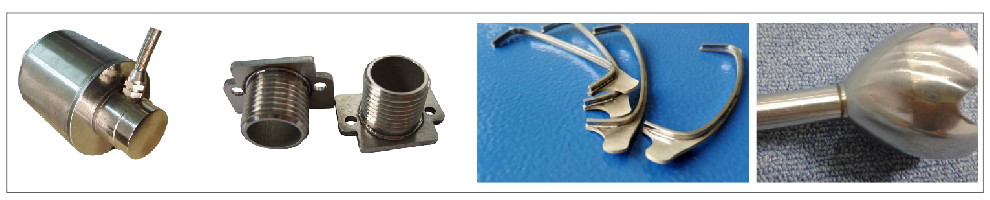

This spot laser welding machine adopt with heavy 2D working table, it easy to adjust the position of working piece according to working requirement, welding spot size can be adjust according to working piece, the welding result clearly showing in CCD camera by digital magnifier, this machine suitable for porcessing some heave product like mould / mechanical parts repair etc.

Description

This is fiber optical laser welding system, the high power laser beam delivery by an optical fiber, so it's ensure to do the long distance welding, the laser focus head is light weight, easy to operate, A flexible mobile arm with straight or turn and tiltable processing head and variable focus range of up to 300mm allow welding in any position whatever, even in deep cavity and holes. Even complex work piece geometries can be handled in an ergonomic working position due to the optional 360 degree swivel lens set of the laser focusing head.

Application

Lt is mainly use in mould & plastic industry,which adopts laser high energy focusing to effectively process tiny broken parts of mould. Such as:repairing all kinds of mould cracks,small holes,collapse,sealing edge and other tiny parts.It has irreplaceable advantages while compare with traditional welding like high accuracy rate,high speed,depth,strength,no holes after processing,can polish into shining surface after welding,especially suitable to repair mould which require polish.

Advantages

1. Importing the advanced technology from German, using a unique design of overall structure, suitable for various medium and small mould repairing.

2. Using the ceramic reflectors that import from UK (200W is ceramic reflector and 300/400W is golden laser reflector). It can resist corrosion and high temperature. Its lifetime up to 8-10 years.The xenon lamp lifetime more than eight million times.

3. Small range of heat, the work piece will not be deformed, no stomata.

4. It can weld in narrow position, welding deeper, and would not hurt the edge.And it wouldn’t make the mould deformation.

5. Parameter adjustment using intelligent remote control, operating simply and fast .

6. No need to modify the mould,it can save a lot of material, labor and time costs.

7. It can work 24 hours continuously.