Fiber laser cutting machine

Model No.: JLC3015LC

The basic-part of the machine: the machine frame is processed with 5axises high-precision CNC equipment throughout thewhole process, the processes of cutting / grinding and tapping screw holes for motion system are completed in one time on the same machine tool, it greatly improved the assemble accuracy of motion system, avoided the error due to machine tool shifting between different process, adopts deep-penetration welding technique and delayed numerical-control low temperature annealing, completely release the inner-stress that generated during the splicing process of the machine frame, ensure that the machine frame will not deform in long-term and high-speed movement. all main parts of machine are adopts famous brands in the world with 20 years matured laser machines assembling experiance, the excellent performance of the machine is leading the laser industry.

Laser cutting machine CNC control system, computer operation, can guarantee the quality of cutting, cutting work more convenient, the operation more simple;Gantry machine tool structure, high damping lathe bed, good rigidity,can withstand the high velocity and acceleration;Exchange of workbench configuration, shorten the standby time,improve the work efficiency more than 30%; | |

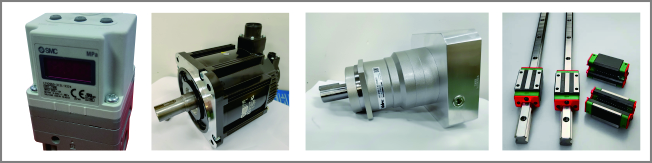

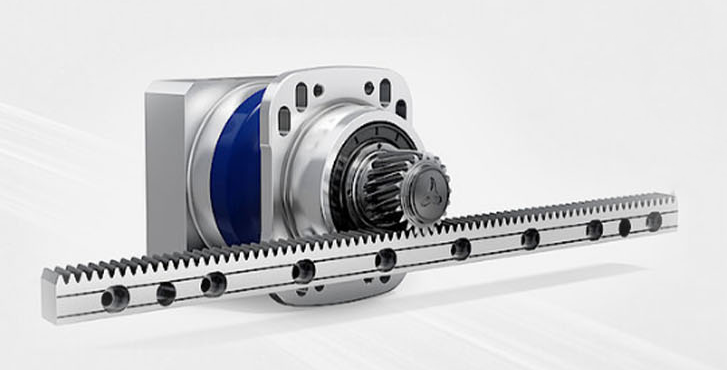

The aircraft with imported ac system driven and imported transmission system, machine tool motion mechanism adopts imported gear rack drive, linear guide, ensure the high speed, high precision, high reliability;Rack and guide rail seal protection device used to prevent oil free friction movement and dust pollution, improve the service life of the transmission parts, ensure the accuracy of machine tool movement;Laser cutting head import capacitance non-contact high tracking system configuration, responsive and accurate, and avoid cutting head and processing plate collision, and can ensure the cutting focus position, ensure the quality of cutting stability; |

Features 1.Adopt industrial heavy duty steel welding structure,Thermal aging treatment,will not deform after long time using. 2.Configure with Hiwin linear rail,high accuracy grinding type gear and racks,Motovario reducer for all axis, to ensure durable and high precision for long time processing. 3.Professional Cypcut control system, can design ant graphic and letters as you like, operating simple, flexible and easy. | |

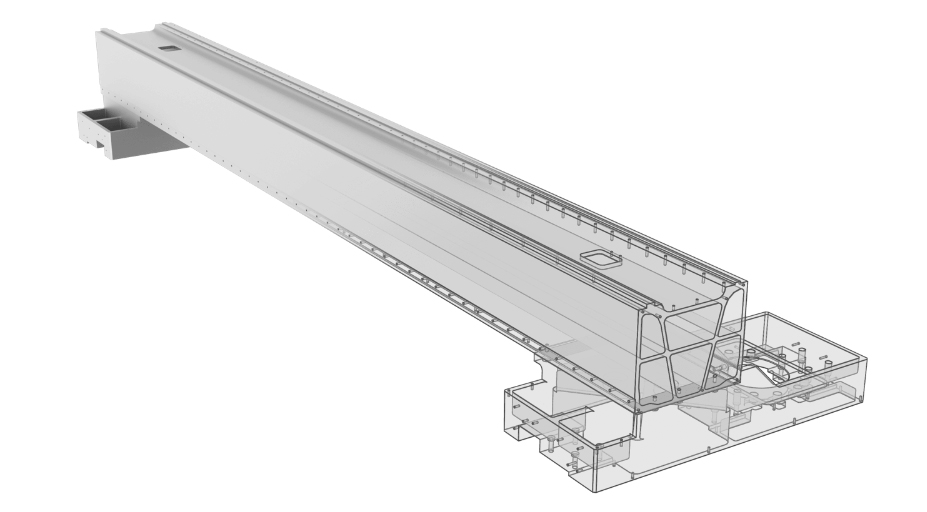

| Cold drawn extruded aluminum beam

Manufacturer use cast aluminum beam which is don by 10-ton steel mould with better rigidity,And the weight is 1/2 lingter than traditional welding iron gantry. |

| SAMPLE DISPLAY | |

| |

Plate Welding Heavy Work Bed

| |

1.Quality Control Skilled and strict Quality Inspection Team is available during the material purchasingand production procedure. All finished machine we delivered are 100% strictly tested by our QC departmentand engineering department. We will provide detailed Machine pictures and Test videos to customers before delivery. 2.OEM Service Customized and OEM orders are welcome due to our aboundant experiences.All the OEM services are free, customer only need to provide us with your logodrawing. function requirements, colors etc. No MOQ required. |